The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Table of ContentsA Biased View of Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand SpecialistsGetting My Motorcycle Parts New Zealand Specialists To WorkThe Main Principles Of Motorcycle Parts New Zealand Specialists Some Known Facts About Motorcycle Parts New Zealand Specialists.The Ultimate Guide To Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists PDFsMotorcycle Parts New Zealand Specialists for Dummies

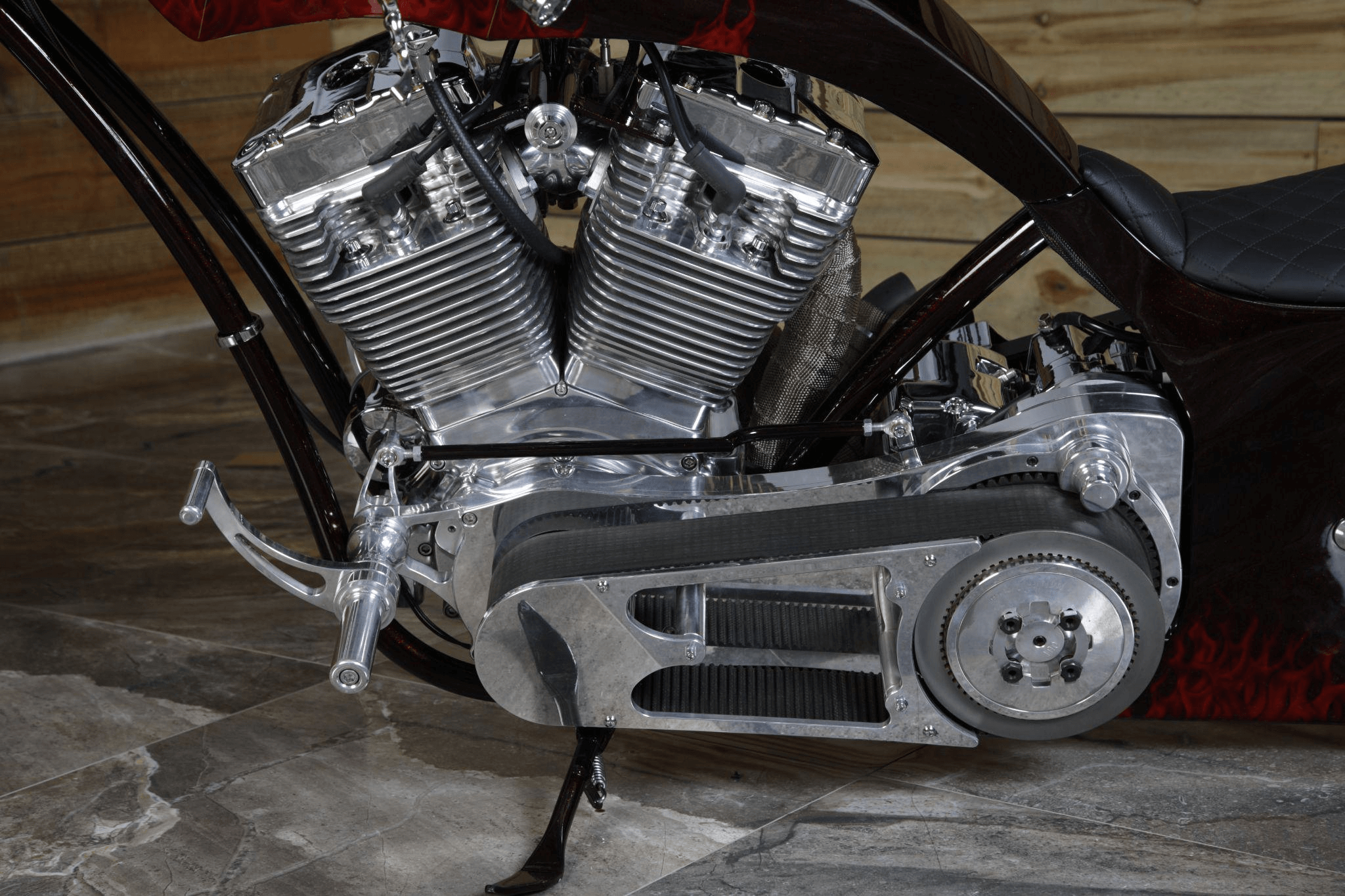

Get to out to one of our experts today.CNC machining technology is quickly coming to be the centerpiece of lots of various manufacturing procedures around the globe as a straight result of its many advantages over other approaches. In addition, the markets that manufacture bikes have actually hopped on board with this pattern. One of the most ingenious firms are now creating their engine elements and wheels using machining techniques originally developed for motorcycle parts.

You might be wondering why we utilize. Currently that we have your attention let us describe the rationale behind this contemporary growth in the motorcycle production sector.

Not known Incorrect Statements About Motorcycle Parts New Zealand Specialists

Additionally, you have full control over the appearance of the components, also to the minute details. Sometimes, motorcyclists might decide to beautify their ride by installing aftermarket parts or customizing the bike's transformation. When once again, computer system mathematical control (CNC) machining is one of the most functional method. Upgrades might be of any kind of type and style you desire.

The 3-Minute Rule for Motorcycle Parts New Zealand Specialists

CNC machining may be made use of to make mostly all of a bike's metal and plastic components. To proceed, we'll talk about a number of machined components for bikes. As opposed to those on cars, wheels on motorcycles have a tendency to be extra noticeable. Because of this, the bike's looks may be enhanced with the ideal modification of these wheels.

When customizing the wheels, the disks are where the emphasis must be. Most of them are constructed of light weight aluminum. Light weight aluminum alloys are widely known for the outstanding machining capabilities that they have. Milling procedures are made use of to get the preferred degree of wheel modification. An additional element of the motorbike that may be customized is the tires.

The 5-Second Trick For Motorcycle Parts New Zealand Specialists

When it involves an automobile (or a motorbike), one of the most essential element is the engine. A number of individuals mention it as the "heart" of the auto. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and need layouts with a high degree of accuracy.

Lighting is one more complicated facet of personalization. Use just high-grade products, however, considering that these lights are essential for the safety and security of motorcyclists and other vehicle drivers or people when driving, particularly at evening. Motorcycle fronts lights have three almosts all: the bulb, or light resource, the lens, and the housing. Specifically, we customize the lens and the housing.

Milling procedures with a remarkable finish would lead to the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the other hand, is not made up of vulnerable materials; rather, it is built out of hard polymers that can be machined into even more detailed patterns.

Indicators on Motorcycle Parts New Zealand Specialists You Should Know

Motorbike makers often cast these components, but just for the manufacturing of bespoke parts. Machining on 5 axes in today's globe is the means by which any kind of layout shape might be recognized.

Select Runsom for your customized motorbike components! We have the ability to produce difficult and stylish elements making your bike incomparable.

Below are a few instances of steels usually made use of in motorbike element machining. Light weight aluminum is the main product used by business specializing in creating personalized motorcycle elements to develop a lot of these parts. In the past, we would develop our engines out of cast iron. On the various other hand, aluminum is swiftly coming to be the material of choice, partially as a result of the reality that it is more lightweight.

Zinc refers to one more metal that is extremely light in weight and has wonderful machining qualities due to its high mechanical strength. This product might be developed into virtually any shape and maintains its dimensions well. Even mission-critical view it now components that need a high degree of precision might take advantage of their usage.

Motorcycle Parts New Zealand Specialists for Beginners

One more steel that sees heavy use in the production of CNC-customized elements is magnesium. It is amongst the lightest metals that are currently obtainable and has outstanding machinability functions and strength proportionate with its reduced discover this info here weight. One of the drawbacks of magnesium is that its dirt might conveniently ignite.

As a result of its premium machinability and weldability, stainless steel is an alloy that is specifically fit for CNC procedures. Along with this, they have wonderful corrosion resistance and a high visual appeal. Their most common use in creating various motorbike elements is bolts, such as screws and screws. Their reduced vulnerability to oxidation and rust makes them suitable for this usage.

7 Easy Facts About Motorcycle Parts New Zealand Specialists Described

It appears that CNC turning and crushing are the fundamental processes. In addition, it calls for keeping bars of product, most usually plastic or steel, in setting and then twisting a cutting device to eliminate sections of the product as the product is transformed.

These techniques are equally essential and produce components with high accuracy and constant top quality. The processes assist boost the general high quality of the machined bike parts.

More About Motorcycle Parts New Zealand Specialists